|

| March 10, 2015 | Volume 11 Issue 10 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Sheet metal tips: Intel designs better data servers with PTC Creo software

By Geoff Hedges, PTC

When it comes to microprocessors, Intel is a household name. The company's "Intel Inside" sticker decorates PCs everywhere. And lately, you can see the chipmaker's iconic logo on smartphones and tablets too.

Behind the consumer products

While the company continues to grow its visibility in consumer products, it's also building up its line for data centers and data farms -- those rooms full of racked compute and storage server systems that manage an organization's big applications, like PLM, ERP, or CRM systems.

"If you want to know what the new Intel looks like, one place to look is at Intel's data-center group," said Intel President Renee James. "Our vision is that if it computes, it does it best with Intel inside, and our success in the data center is a leading indicator."

Intel is helping the IT industry stay on top of this avalanche of data with products like its E3, E5, and E7 Xeon processors for high-performance computing. The company even goes beyond the chipsets and sells boards and entire server systems including chassis.

Enterprise Servers

We talked recently to Glen Hanna, a System Platform Architect, about his role in the server business at Intel and how PTC Creo fits in. The CAD software is more prevalent than you might think in a company known for its work in semiconductors.

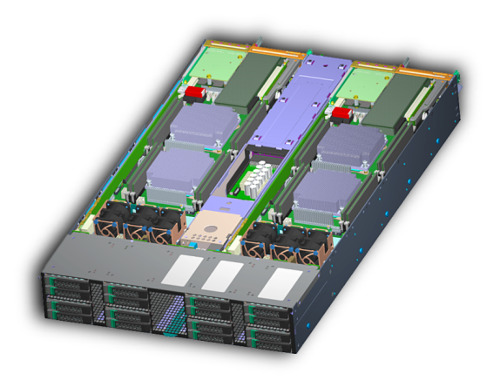

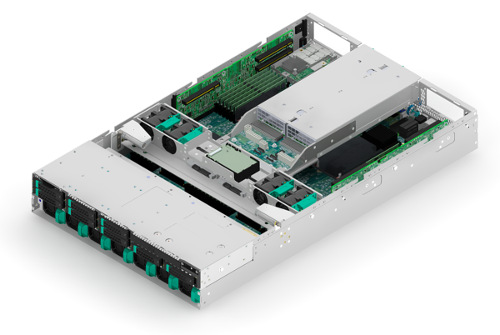

Hanna's architecture team specializes in rack servers designed for enterprise, cloud, and storage market segments.

"I'm responsible for thermal and mechanical solutions. I take all the building blocks and upcoming technologies, and put together concepts of what that might look like in future platforms," says Hanna. "I look at processors, boards, peripherals, and power supplies to develop solutions that are cost effective, easy to use, and meet customer requirements."

Hanna is among 500 engineers and designers at the company who use PTC Creo. For Hanna, the software helps him develop the chassis enclosures that contain the server components.

He says that while the company has been using PTC products for a long time, the changes in the latest release have been especially useful to him.

"We design a lot of sheet metal," he says. "With PTC Creo, the corner reliefs are much more robust [in recent versions], while the flat-panel viewer helps us check for overlaps."

Here's a quick video that talks about PTC Creo's sheet metal capabilities:

Development process

To understand how Intel measures the success of its design software, it's also helpful to understand its development process.

Products pass through four phases: Alpha, Beta, Silver, and Gold. At the end of the Alpha phase, developers should no longer add features to a product. Beta signals that the design is complete. Silver and Gold are the QA and approval phases.

"What we've seen in the past," says Hanna, "is the later you make fixes, the more expensive it becomes. Late changes in the Silver and Gold phases impact the hard tools, like stage and progressive dies, molds, and fixtures; changes like that can cost hundreds of thousands of dollars."

So, architects and engineers strive to get the products complete in the earlier stages. There are several ways PTC Creo helps them do more sooner:

- Product developers can quickly leverage files from partners and vendors, even when they're created in different systems. With PTC Creo Flexible Modeling Extension (FMX), designers edit geometry and features from these outside systems easily.

- Concurrent Engineering and top-down features help the Intel team download and work with large complex assembly files. What used to take minutes now takes seconds, says Hanna.

- Newly introduced features for patterning and sheet metal improve productivity and add better reliability to resulting designs.

- Cross-sectioning helps the team catch problems not visible with interference check alone.

As a company with 100,000 workers, Intel employs people with many diverse backgrounds and experience in other CAD software. But, Hanna says, "Our corporate standard for design is PTC Creo."

Published March 2015

Rate this article

View our terms of use and privacy policy